Description:

Description:

The main components of 202 stainless steel pipes are alloy elements such as chromium, nickel, manganese, and silicon, among which the chromium content is relatively high, generally between 17% and 19%.

- Features of 202 Stainless Steel Pipe:

202 stainless steel pipes have very good corrosion resistance and are particularly suitable for use in atmospheric and moderately corrosive environments.

202 stainless steel pipes also have good oxidation resistance and high temperature resistance. They can withstand pressure at high temperatures without bending or damage.

- What is 202 stainless steel?

202 stainless steel is a variant of the 200 series stainless steel category, and its national standard name is 1Cr18Mn8Ni5N. 200 series stainless steel belongs to low-nickel high-manganese steel, with a nickel content of about 5% and a manganese content of about 8%. It is a nickel-saving stainless steel.

Specifications:

Specifications:

|

Product name |

202 stainless steel pipe |

|

|

type |

steel tube |

|

|

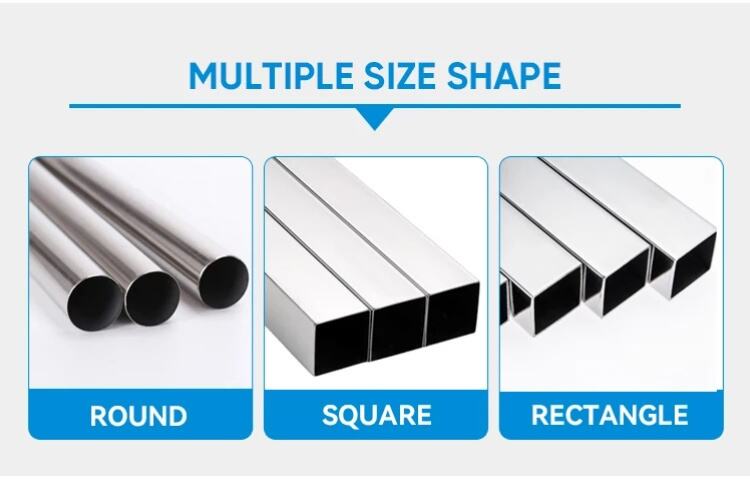

Outside diameter |

Round tube |

4mm-200mm |

|

Square tube |

10*10mm-100*100mm |

|

|

Rectangular tubes |

10*20mm-50*100mm |

|

|

Wall thickness |

0.6mm-6.0mm |

|

|

length |

1-6 meters, length can be customized |

|

|

standard |

ASTM / AISI / JIS / GB / DIN / EN |

|

|

surface |

Black, glossy polishing, rough turning, matt finish,NO.4, BA, etc |

|

|

Scope of application |

Common applications for stainless steel tubing include food processing, textile operations, breweries, water treatment plants, oil and gas processing, fertilizers and pesticides,Chemical Applications, Construction, pharmaceuticals, auto parts, etc |

|

|

certificate |

ISO / SGS / BV |

|

|

Production technology |

hot rolling /Cold rolling |

|

|

Edge processing |

Edging / Trimming |

|

Chemical Composition of 202 Stainless Steel Pipe:

|

Grade |

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

202 |

≤0.15 |

≤1.0 |

7.5~10.0 |

17.00~19.00 |

4.00~6.00 |

≤0.03 |

≤0.06 |

Mechanical Properties of 202 Stainless Steel Pipe:

|

Grade |

tensile strength σb (MPa) |

Yield strength σ0.2 (MPa) |

Elongation δ5 (%) |

hardness |

|

202 |

≥520 |

≥275 |

≥40-50 |

≤207HB;≤95 HRB;≤218HV |

Physical Properties of 202 Stainless Steel Pipe:

|

Grade |

density(g/cm³) |

Elastic modulus(Gpa) |

Coefficient of thermal expansion(10-6/ºC) |

Thermal conductivity(W/m*K) |

Resistivity(μohm.in) |

|

202 |

7.93 |

203 |

17.5 |

16.3 |

22 |

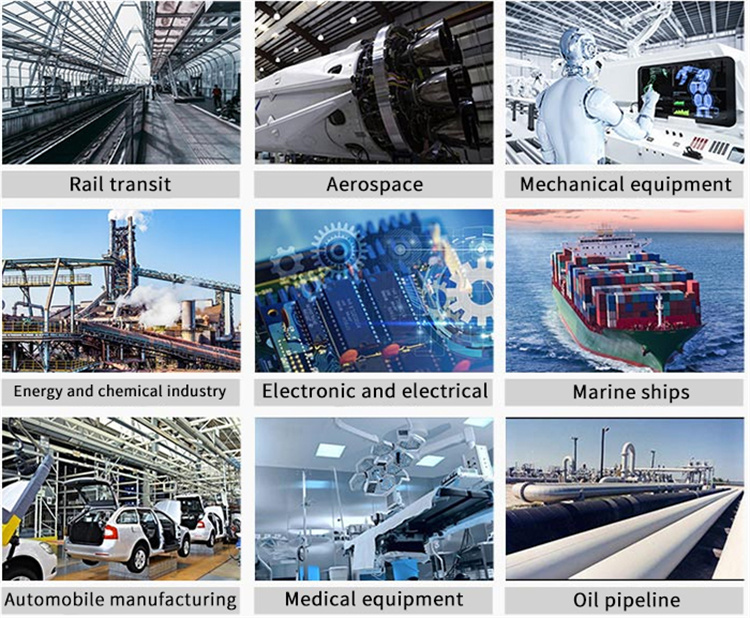

Applications:

Applications:

Construction industry Manufacturing machinery

Automobile manufacturing Household appliances

Chemical industry Pharmaceutical industry

Product Inspection:

Product Inspection:

201 VS. 202 Stainless Steel :

201 VS. 202 Stainless Steel :

When comparing 201 and 202 stainless steel, despite the similar appearance and use in various applications, there are several key points to consider that differentiate the two types.

Composition:

Composition:

Properties:

Properties:

FAQ:

FAQ:

1.Q: How long can make delivery?

A: For stock products, will make shipments in 5- 7 days after receiving deposit; for products need new production for common materials, usually make shipments in 10-15 days; for products need new production for special and rare materials, usually need 20-30 days to make shipment.

2.Q:Can I visit your factory?

A: Sure,welcome to you visit our factory at any time.

3.Q:Where are you?

A: Anyang in Henan Province.

4.Q: What certifications do your products have?

A: We have ISO 9001,BV, SGS, CE, TUV and other certifications.

5.Q:What are your terms of payment?

A:30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100%.Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A.

Tag:

202 Stainless Steel Pipe,China Stainless Steel Pipe manufacturers, suppliers, factory,Stainless Steel Tube,316 Stainless Steel Pipe, 304 Stainless Steel Pipe, 304L Stainless Steel Pipe,201 Stainless Steel Pipe,301 Stainless Steel Pipe,2205 Duplex Stainless Steel Pipe,310 Stainless Steel Pipe,310S Stainless Steel Pipe,Stainless Steel Seamless Pipe,Stainless Steel Welded Pipe,321 Stainless Steel Pipe,316L Stainless Steel Pipe

Copyright © Privacy policy