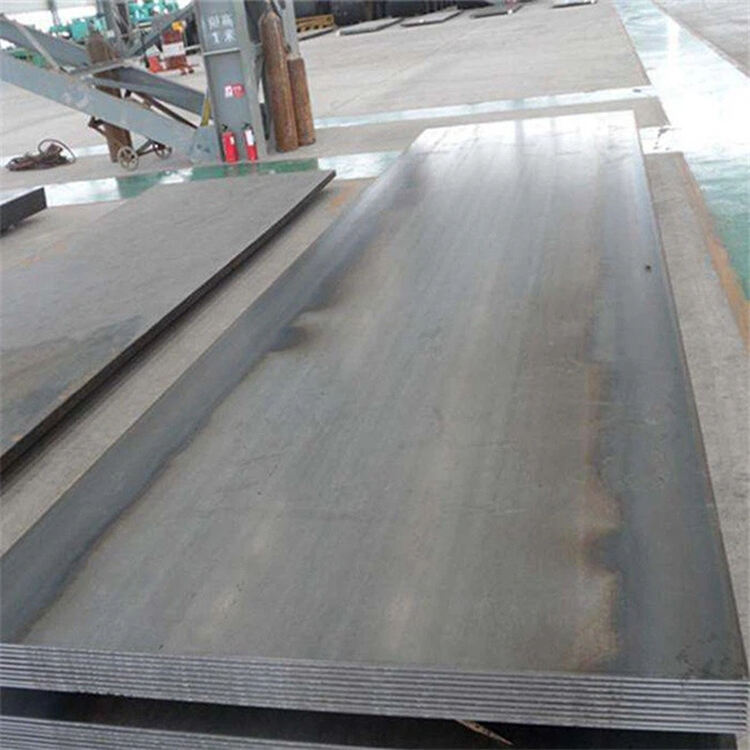

Mn13 is a work hardening steel that has become the foundation of heavy industry. This makes it enormously useful for a wide variety of things, like building and mining, when you need solid materials. In this article, we will get to know more about Mn13 steel; and why it is one of the most highly demanded steels for various industries.

Claims that Mn13 can withstand greater than tensile-extension are bogus. That is, it does not get damage quickly when something hits or impacts on them as alternative materials can be breakable and flexible. This spectacular strength is due to the high content of manganese in Mn13. Manganese is a super element which will make the steel tough,and hard to break. Moreover, Mn13 also is wear-resistant which makes it serve long for next working life without replacingMn13.

Austenitic Mn13 Steel is made up of several different elements according to the specifications outlined in ASTM A128-07Manganese(Rubber ) Mn13 is comprised of the following elements, each serving an illustrious purpose in making it tough and strong. As we referenced prior, manganese is truly significant with regards to guaranteeing the strength of Mn13 and its innocuousness against high impacts. It is also tough because of the carbon in it. Meanwhile, the silicon makes the steel more ductile, so that it can deform without cracking. In conclusion, the characteristics of these elements in with this steel result as Mn13 being a highly versatile and effective material.

When it comes to mining and building, Mn13 material is mostly sought. This is essential in the industries that they currently support because these require heavy-duty machines. The fields for which Mn13 is specifically well-suited are those in which it will comes into many hits and impacts. While for mining, large rocks may fall onto machines and damage them. But Mn13 hardness is enough for this machine. Construction is another area were heavy tools and machinery must be sturdy enough to cope with the requirements of working life, with Mn13 steel ideal for construction-country work.

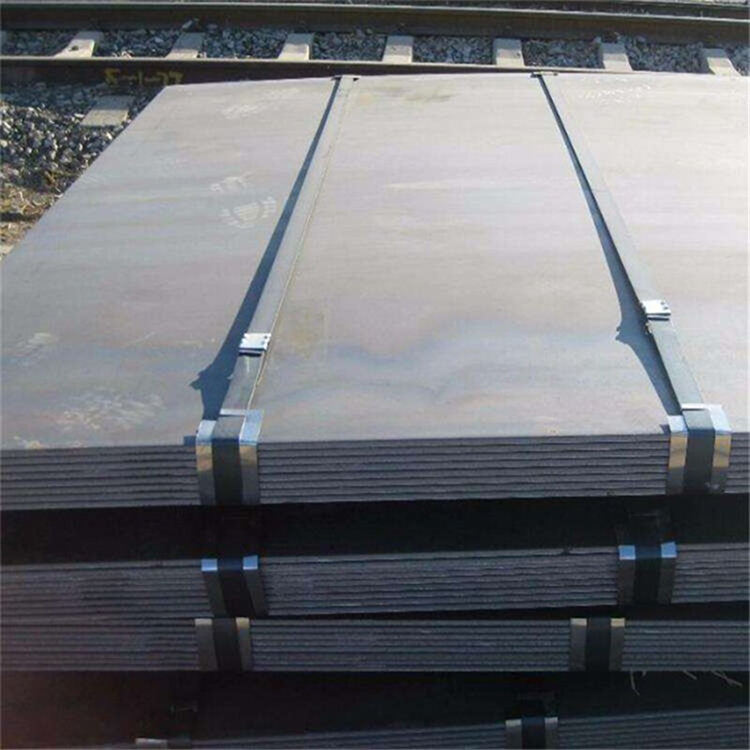

Lastly, Mn13 is incredibly robust and hence helps equipment last much longer than if it were made of weaker materials. Rather than burn out machinery quickly, causing machine replacement every few years, from wear and tear over time machines can last several decades with the help of Mn13. These not only save you money but also cut down on waste. The Mn13 steel can also be used to create vital tools as a blade, hammer and cutting edges. The use of Mn13 steel to create these tools is crucial for both mining and construction, as without them you run the risk that they will not be able to do their jobs effectively and with reliability.

strict compliance international standards, choose and produce high-quality materials accordance Mn13 needs and requirements. With strict quality control and testing, guarantee that each batch products in compliance with the highest standards quality and provides customers with a solid assurance.

use the latest manufacturing techniques equipment in order produce products that durable as well as precise and durable. From the preparation of raw materials to the creation of final products rigorously control each connection to Mn13 consistency reliability product quality.

company provides range products made steel able meet array specifications, Mn13, applications. customers require standard products unique products, we position provide tailored services meet requirements meet needs various industries fields.

Our team is highly trained with years of experience, and are able to provide customers with professional solutions and technical assistance. We place a high value on communication and Mn13 with customers, providing comprehensive post-sales support and consultation to ensure customer satisfaction and trust during the purchase and use process.

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy