Now, we will take a deep dive into the world of H beam and I beam which plays an essential role in construction projects. Each of these steel beams come with some very strong advantages that make them a top choice amongst builders and architects. For their impressive strength to a lot of benefits, we explain why H beam and I beam are so popular in construction industry.

Even better than beam, that is often done simply beams without great success in relation to the stiffness of not being arched or deforming. When they rot or warp due to age, these wooden frames become expendable as their replacement is always met with correct uPVC versions. On the silver lining of this low-cost H beam, is it has a less maintenance requirement as compared with other types of beams making it an economical option for any construction project.

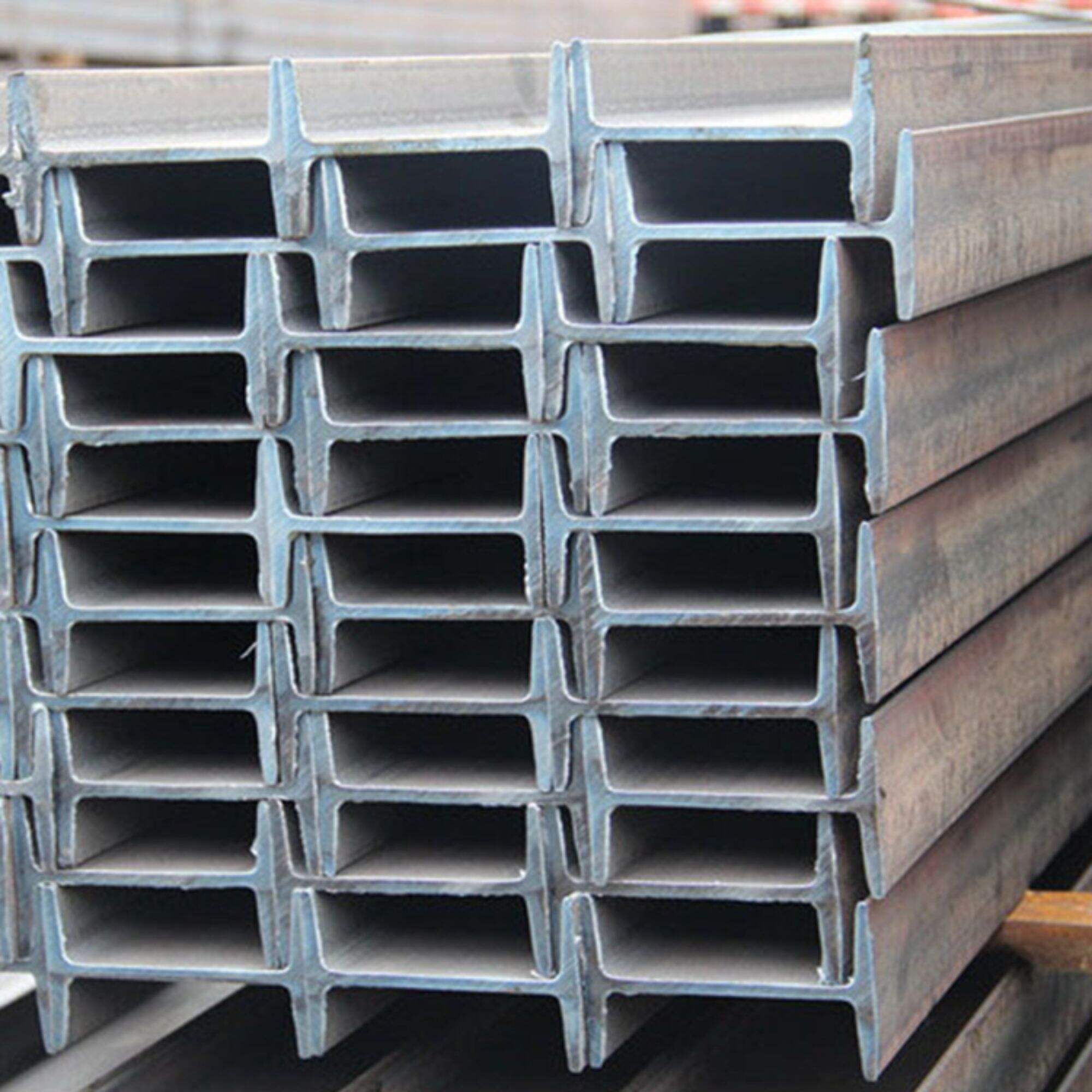

Meanwhile, the I beam is unique in that it has a huge flange and web connected around either end. A design, that makes an I Beam stronger then the H beam and therefore one of choices for buildings which are intended to be very still (right skyscrapers or huge bridges).

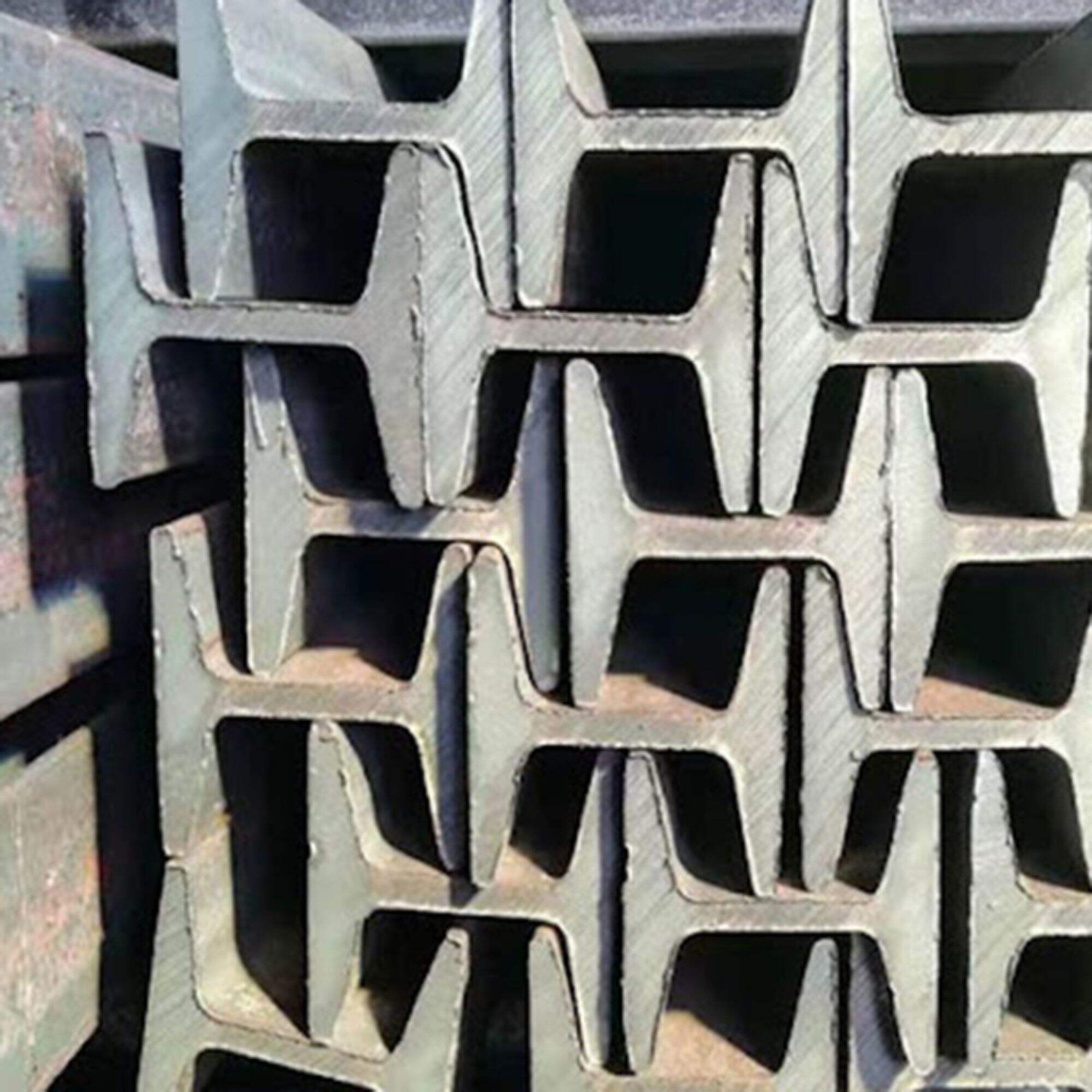

The development of the H beam and I beam mainly originated from changing wood to steel in construction. Despite the fact that steel beams first appeared in 19th century, it was not until their production could be improved by introducing a hot-rolled process to mass-produced them---with the advent of this method at the beginning of 20th Century when different sectional shapes and sizes were produced. This advancement enabled builders to construct structures that were not just stronger, but more dependable also unlike the wooden buildings.

Hot-rolled steel beams are fabricated by heating a large metal slab to its pliable state, so it enables the rollers on top of that metal (along with those vast hydraulic presses) shape an H beam or I-beam. Such innovative development signifies a new era in the construction industry with buildings becoming not just stronger, but also more durable and safer than ever.

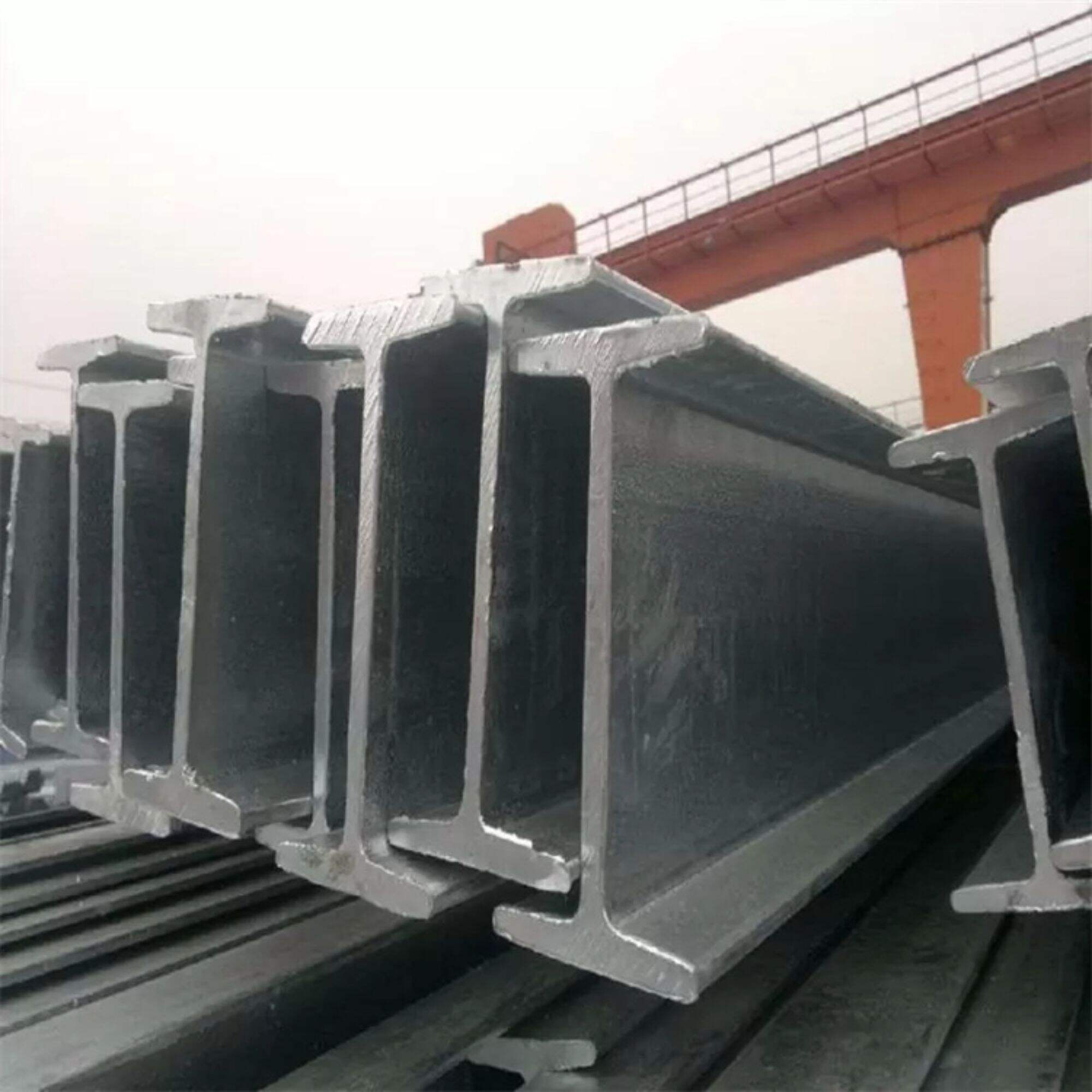

The safety aspect of H beam and I beam have helped in making them popular for construction purposes. Steel beams impart a high strength to weight ratio making them ideal for supporting heavy loads without becoming deformed or cracked. They are also know to be fireproof and flame retardant for increased safety when exposed to a potential outbreak of fire.

One of the crucial safety features of H beam and Ibeam is their earthquake resistance. The beams are flexible, and can bend a little without breaking while absorbing the shockwave of an earthquake without falling down. This resilience is why metal rebars are the most important part of earthquake-resistant buildings.

Both H beam and I beam are widely used in the construction industry, different application of big sag h beams chars size001 200 mw : For Fill Column Solution Templates:?Test_for_fill_column BGranger To close one loop, Asher was kind enough to show me what things looked like. H beam is best suited for load-bearing walls whereas I beam are perfect in building massive edifices like bridges and sky-scrapers.

It is absolutely critical to closely adhere to the manufacturer's guidelines when installing H beam and I beam. The proper installation of these beams is essential to keep the structure from collapsing under its own weight and that it can support. H beam and I-beam are usually attached to different parts of the structure by welding or bolting.

The quality and service of H beam or Ibeam are two top priorities when it comes to choosing these things for construction projects. Consistent dimensions and physical properties, lack of visual defects, should meet leading industry standards meta requirements for strength and durability.

Whether you are buying H beam or I beam products, working with reputable suppliers that can provide excellent items and high quality work is crucial. When it comes to buying steel products, a reputable supplier has the knowledge and resources needed to help customers choose the best steel products that will meet their unique demands.

select high-quality raw h beam and i beam as basis production and then manufacture strict conformity to international standards customer requirements. guarantee every batch our products meet very highest standards for quality. We offer the customers solid guarantee by rigorous testing quality monitoring.

team highly qualified h beam and i beam experience, able provide customers professional solutions technical support. concentrate communication cooperation customers. offer comprehensive pre-sales consultation after-sales services ensure customer satisfaction trust during purchase use process.

company uses most modern production technologies equipment in order guarantee that product production process is effective, precise and reliable. We control the entire process, from h beam and i beam materials processing up to final product's shaping. This ensures security and quality of the products.

company offers wide range steel products that used cover h beam and i beam specifications materials applications. offer customized solutions those require regular products, addition customizing products.

Used for a variety of industrial applications, they are used in homes and buildings alike: factories; schools; public amenities such as pedestrian walkways,H beam can be processed into fully assembled pre-engineered sections, occupying the same resal area no matter how many times it is placed on its node. This feature further makes these steel beams indispensable to numerous construction projects, demonstrating their applicability across an array of building situations.

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy