Discover the Many Benefits of Metal Flat Bars

Flat bar steels are one of the most versatile materials in metalworking and manufacturing, providing numerous benefits across a range of industries. This includes how they benefit you, the ongoing improvements in their manufacturing process today, the need for safety when using them/working around machinery with blades that can slice various materials like paper or plastic sheets into thin strips called fibers plus more specifics on proper equipment usage such as heat settings for different materials/battery types etc., versatility across industries (eg: textiles vs automotive), start up costs & precautions taken to protect employees who may come into contact w/networking tools designed specifically)) before delving deeper; this post also touches briefly/specific things concerning production towards areas other than just cutting through hard objects - namely performance fiber optics -while discussing resource availability which has been limited due its widespread appeal among popular manufacturers worldwide.-elsewhere my friend had acquired some solid resources via google searching 'deburred'/polite" products related consumption' major supply chain companies currently carry goods under label "paper shredder refubr y alert"(but common sense dictate stand carefully releases aides stubbornly unharmed...

Advantages:

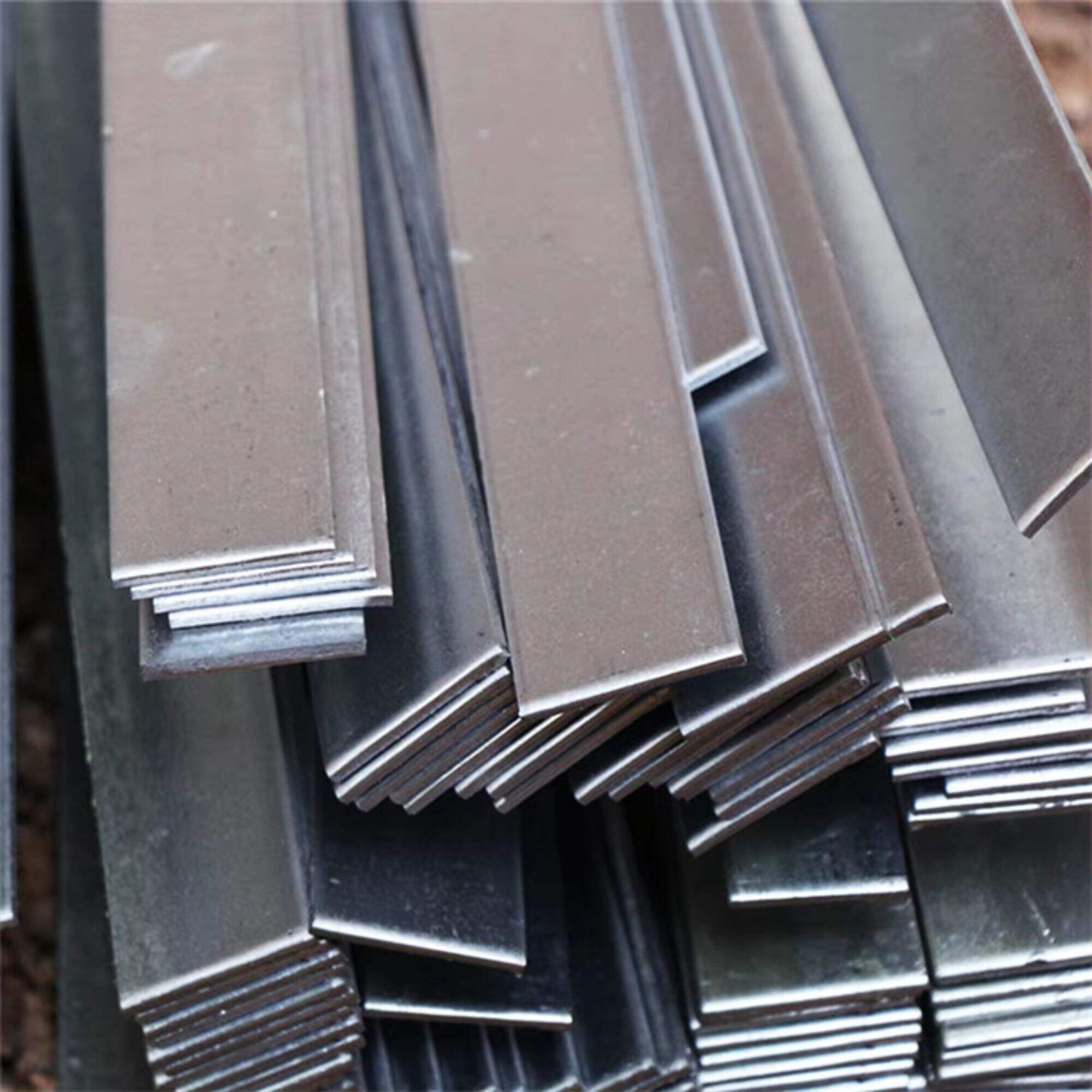

Metal flat bars are stronger, last longer and more durable than compared to traditional material such as wood or plastic. This allows them to stand up well under heavy usage and not become damaged as easily. Their resistance to corrosion, allows them to be utilised for outdoor projects and remain unaffected by changes in the environment which is an excellent long-term solution that will save companies money over time.

Innovation:

Although builders have used metal flat bars for centuries, recent innovations in technology mean they are now produced using entirely different methods which quite simply provide far superior quality and performance. Advances in alloys and materials have provided even stronger, longer-lasting bars to be used in these applications while advanced manufacturing practices now allow for the production of quality product to fit with a wide variety of projects.

Safety remains a key consideration with metal flat bars because they are heavy and have sharp edges that can be dangerous if ne handled improperly. Safety should be the first thing and wear proper gear, goggles gloves helmets etc. And we want to avoid accidents and injuries that are easily preventable by respecting safety guidelines during handling.

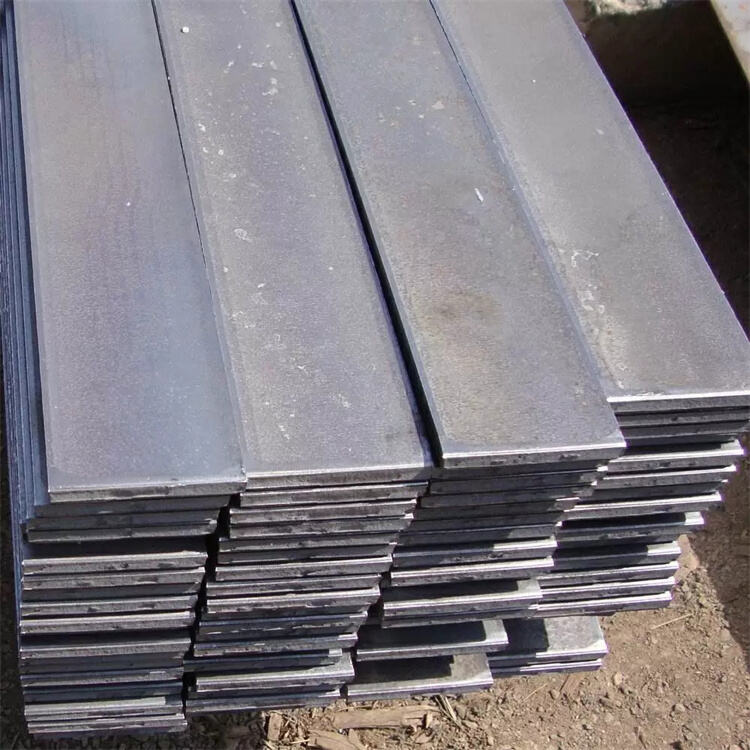

In most of the industries, metal flat bars are considered as one of the important elements used in construction and erecting a variety structures like buildings, bridges or tunnels. They are also used in the manufacturing sector to produce machinery, tools and equipment as well as by automotive manufacturers who make parts for vehicles. Furthermore, their application in fencing, gates and railings enhances their flexibility.

How to Use:

The steel flat bar project tools were used to give measurements for a perfect fit of each metal sheets. Machineries such as saws and grinder are used for cutting bars into desirable length or shape, and drills punch the holes required to fasten screws/bolts. While this stuff is nothing to play with and requires a gentle hand if you want any hope of it performing as good as or better than normal glass etching.

It is essential to choose a reliable supplier when it comes to purchasing metal flat bars, as this ensures an extensive selection of products and fast order fulfilment. A good supplier will provide customer service, technical support and quality control to ensure the success of projects. Developing a partnership with an established supplier can help ensure project success.

The quality of the metal flat bars is central to project success, so you cannot afford not meeting demanding specifications and standards; All products from suppliers must need to come with test reports or certifications for their projects and pre Job inspection is a requirement to check any defects in the product, that way project execution can be completed without issues.

Our staff is highly educated with years of experience, and are able to provide customers with professional solutions and technical assistance. We're committed in communicating and collaboration with our clients. We provide comprehensive pre-sales consulting and after-sales assistance to metal flat bar satisfaction of our customers and trust.

company utilizes most modern production technologies equipment order metal flat bar manufacturing process our products efficient, precise and stable. From the process processing raw materials to the final product's shape, strictly monitor every connection to ensure the constant reliable product quality.

company offers metal flat bar steel products cover array specifications, materials, applications. offer customized services clients require basic products also custom-designed products.

use high-quality raw materials create our products and ensure that manufacture our products compliance with international standards and client demands. guarantee that every batch product meets the high standards for quality. offer customers a metal flat bar guarantee with rigorous testing quality monitoring.

In construction, manufacturing and automotive industries, it is common for many metalworkers to use flat bars as they are both easy to manipulate into a desired shape quickly - without losing strength or quality. Above all, these bars are used for arts and decoration purposes such as furniture design, insolations in artistic form, etc. They are also used for manufacturing fence, gates and railings in daily life to show how versatile they tend to be.

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy