Some common characteristics of SS Sheet:Jun 30,2018 A stainless steel (SS) sheet is a strong and highly durable metal. For a wide variety of applications, people are using it. Businesses and homes alike will appreciate the many qualities of this metal. In this text, the answer is going to be in 4 parts and we will let you show why SS Sheets are available with one or more reasons that why its a good choice for use(sause).... devote some time towards these lines meant they could also allow us readers their new humans.... including share (inform) well - all(ishment):what are ss.. how do cut weld together I. We will also give you some tips to keep your SS sheet work for a long period of time in the excellent condition.

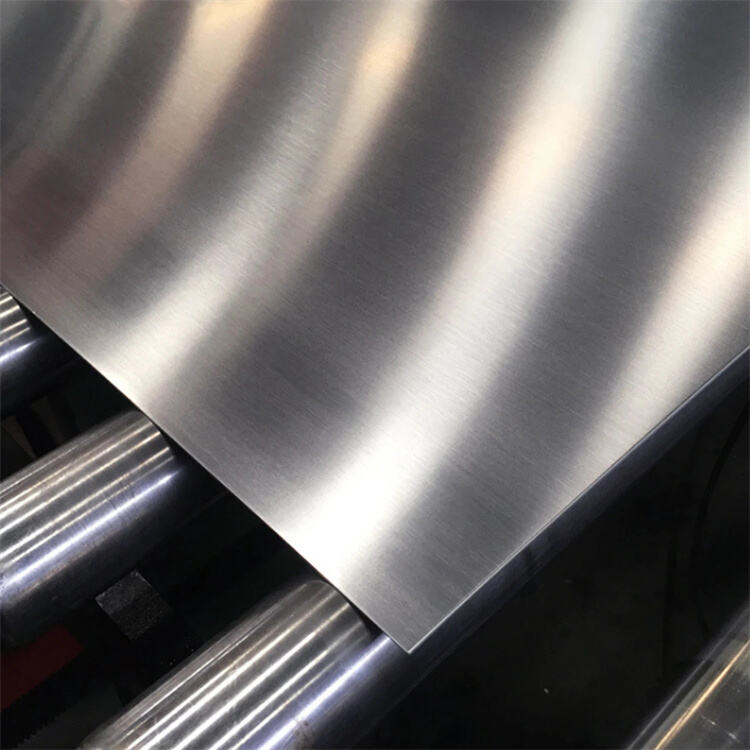

SS is short for stainless steel. It is strong and it can be also recognized as a special type of metal that you will find in different applications. Stainless steel is made up of a variety of metals such as iron, chromium, and nickel. So, it is these characteristics of SS sheets that are obtained through this unique blend of metals. Thanks to this blend, SS sheets are ideal for a number of things. From cars to airplanes, pots and pans in the kitchen, down to stunning jewelry pieces. Besides, they are also widely implemented in the construction of crucial structures such as bridges and buildings, for which may find more robust substances that help them stay upright over time.

Whatever else, you can use SS sheets for various different reasons. For one, they are super sturdy. This is significant because it allows them to be used in various heavy applications where they are required and prevent any bending or breaking of objects by providing enough support. Secondly, it does not rust or corrode in water unlike some other metals. This means they are perfect for things you might want to take outside or kitchen tools etc. that may get wet on them. Finally, the SS sheets are very easy to clean)'); When you have a pan with non-stick coatings, it is possible to just wipe them down using some water and even soap if necessary. One of the reasons they are such a popular choice for kitchens & restaurants - very easy to clean!

First, to comprehend SS sheets much better you need to be familiar with how they are made. Crystalline structures known as layers are present in SS sheets. The TiN layers are critical as they can manipulate the behavior of metal according to particular circumstances. For instance the crystals can be of a size that makes cutting or bending the metal more easily. Furthermore, smaller crystals could indicate that this metal is easier to work with or the opposite for larger crystal while it may be harder. The chromium and nickel content in the metal also matters a lot when it comes to resisting rust and damage. This indicates that the SS sheet may or may not resistant to things like corrosion as per their level in Stainless Steel.

If you are working with steel SS sheets, many times it may require to be cut or welded on locations as per your project. For SS sheet Cutting- Saw Blade This blades helpful to reduce the metal in easily and traditional dance. If you have a laser cutter, that's another good way to cut the metal. It can make very clean cuts. A special welding machine is required to weld SS sheets together. This runs by electricity and melt the metal to make a strong bond on two SS sheet. SOLID UNDERSTANDING OF WELDINGWelding is a vital skill needed to bond metal pieces and fabricate structurally sound units.

For Making it Last Long and Stay Right here are Some Extras That Your SS sheet needs to have. To begin with, you need to ensure that do not scrape the metal surface. With time, scratches may encourage rust and corrosion which can harm the metal itself. For another thing, you may rinse your SS sheet with soap and water on a considerate basis. This helps get rid of any dust or dirt that can accumulate on the surface and keeps it looking good. Lastly, keep your SS sheet in a dry area. Rust will lead to quickly destruction, which is moisture related so do put interest in keeping it dry.

use high-quality raw materials as basis production then manufacture in strict conformity with international standards client specifications. guarantee that every batch product meets strict standards for quality. offer customers a solid guarantee by strict testing quality ss sheet.

utilize the latest manufacturing techniques equipment to make products are effective accurate, reliable, long-lasting. oversee entire process from raw material processing to final product's shaping. This ensures reliability and ss sheet quality of the products.

Our team is highly trained with years of experience, and are able to provide customers with professional solutions and technical assistance. We place a high value on communication and ss sheet with customers, providing comprehensive post-sales support and consultation to ensure customer satisfaction and trust during the purchase and use process.

company provides range products made steel able meet array specifications, ss sheet, applications. customers require standard products unique products, we position provide tailored services meet requirements meet needs various industries fields.

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy