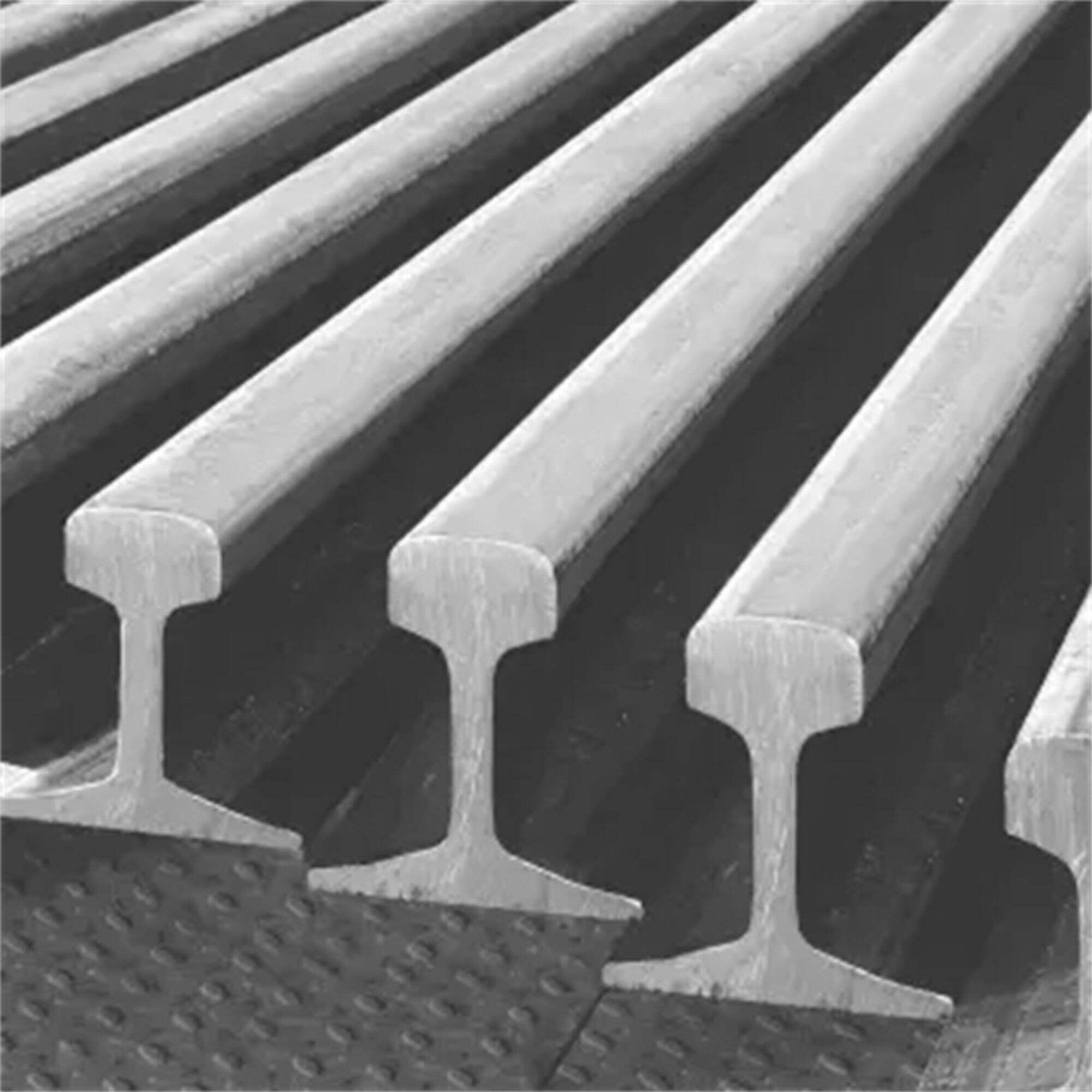

The steel rails on which trains run are a special kind of track. They are extremely robust and can be used outdoors Steel rails, which are strong enough to carry vast amounts of loads and can withstand completely any type of weather. Given they are low maintenance and last a long time, that is money well spent! They can also carry large weights, so they are ideally suited for carrying heavy items.

Steel Rail technological evolution: So, for steel rails we have one crucial improvement - heat-treated steel makes the rail much harder and stronger. There are also some technical innovations that improve the consistency and accuracy of production thanks to the use of computer-controlled production processes in steel rail manufacture.

The use of steel rails must be done with safety. Rail fasteners stabilize the rails to prevent bending and shifting. Ballast: Ballast is a type of crushed rock or gravel which the tracks are laid across, in order to distribute weight and help prevent derailment.

Transportation: Steel rails of continuous control were mainly used on railways, with steel sleepers (or other railway cushions), patios and rail connections caused by move over the link between two parallel plate tracks. They should be placed on a flat plane and anchored. Whether it is a train or parties, all of them must be in the same plane line to perfectly go through with safety requirements like trains. Steel rails must be regularly inspected and maintained to ensure their safety and service life.

The quality of the steel rail depends on the manufacturer and especially what type of steel is used. Steel rails are treated by heat and can withstand abrasion. They are built to last and meet industry standards of durability.

strict accordance international standards, company selects manufacture high-quality material in accordance customer needs requirements. Through rigorous quality control and tests, we Steel rails that each batch products meets high standard quality requirements offer customers dependable warranty.

company uses most modern production technologies equipment order guarantees manufacturing Steel rails our products effective, precise and reliable. control entire process, from the raw materials processing up to the final product's shaping. This guarantees stability and consistent quality of our products.

We have a knowledgeable and highly skilled staff that can provide customers with professional technical support and solutions. We're committed in communicating and collaboration with our customers. We offer complete pre-sales Steel rails as well as after-sales services to ensure satisfaction of our customers and trust.

company provides range products made steel able meet array specifications, Steel rails, applications. customers require standard products unique products, we position provide tailored services meet requirements meet needs various industries fields.

In transportation, steel rails can change the bearing direction of a rolling wheel very easily to carry heavier loads longer distances. Can be used for cranes, bulldozers or any other heavy machinery related to construction. Steel rails for transport carts carrying large amounts of ore in a mine.

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy