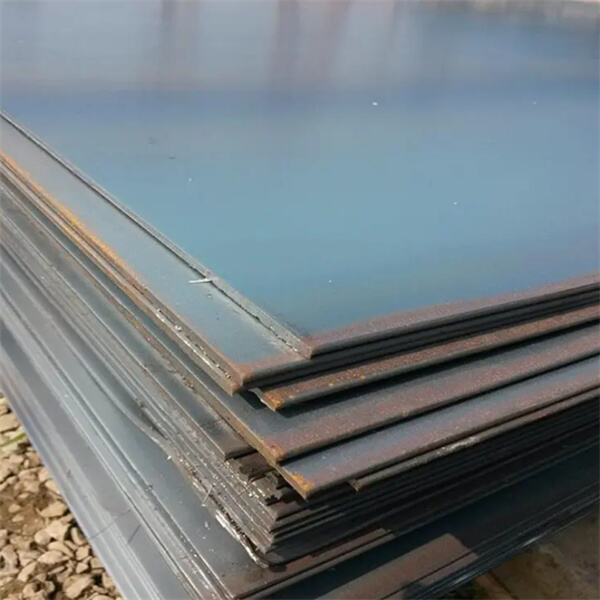

Wear plate steel is a kind of high quality, extremely durable steel used continuously on mining or quarry equipment. This is built for abuse (highly utilized plant machinery). Meaning that wear plate steel can withstand all forms of abuse from animate parts rubbing together or cutting as well as heavy impact abrasions exerted during operation. You will commonly see this type of steel at factories, building sites and other area where machines labors every day.

Chromium carbide wear plate steel - it is quite solid, works well when scratching and in severe use cases. It is commonly used in mines where they can use it to carry rocks and other very heavy things back up to the top of the ground; likewise with cement plants as these are fairly ruff and tough environments.

Hardox wear plate steel - Wear and abrasion resistant, says it afefercely It is very common in construction, i.e., trucks and trailers so they can support their load without breaking down or wearing out, also used on farm equipment to keep it from braking.

Tungsten carbide Super hard wear plate steel - This material is for highly abrasive and allow to use a type of cold working which provides very good wear resistance. It is recommended for heavy-duty industries like Oil Gas, Mining and Construction where the equipment are exposed to hostile environmental condition.

In the massive business produced, wear plate metal is quite necessary on account of reality that it allows devices and automations to take pleasure in for any lengthier time. Horizontal splitters may fail at any time, but wear plate steel will prevent them for most companies. This may result in unnecessary expenses to repair machines or an even loss of time when the machine fails. Crusher wear plate is mainly used to withstand the impact and pressure from stone, reducing direct friction with other abrasive work (eg transportation) under load conditions With longer working life of normal steel onboard twice or more as high for millions tons costs at target.

Less downtime -- anywhere there is a repair invoice for this will be reduced at which business isn't safety measures to get tenants. This steel wear plate ensures that they are less likely to break down, which translates into more uptime for these machines and a lesser need for repairs.

Easily Wear Plate: When the wear plate is damaged or has been used for too long, it may not be available any longer. After the process of installing lamps or wipers and fastening them with accessories, then any kind failures that may occur are prevented so this equipment cannot be inactive at anytime during operation.

We have a knowledgeable and highly skilled staff that can provide customers with professional technical support and solutions. We're committed in communicating and collaboration with our customers. We offer complete pre-sales wear plate steel as well as after-sales services to ensure satisfaction of our customers and trust.

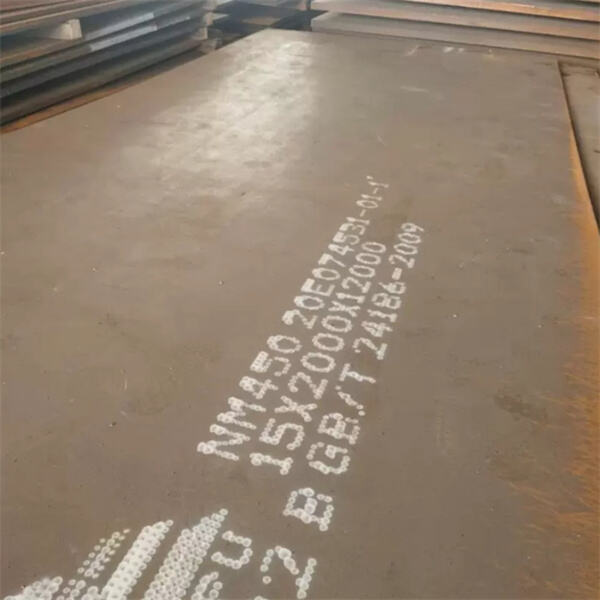

pick high-quality raw material wear plate steel products then manufacture in strict conformity with international standards customer requirements. Through strict quality control testing, we make sure that every batch our products meet the strictest quality standards give our customers reliable warranty.

company utilizes most modern production technologies equipment order wear plate steel manufacturing process our products efficient, precise and stable. From the process processing raw materials to the final product's shape, strictly monitor every connection to ensure the constant reliable product quality.

company offers wear plate steel steel products cover array specifications, materials, applications. offer customized services clients require basic products also custom-designed products.

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy