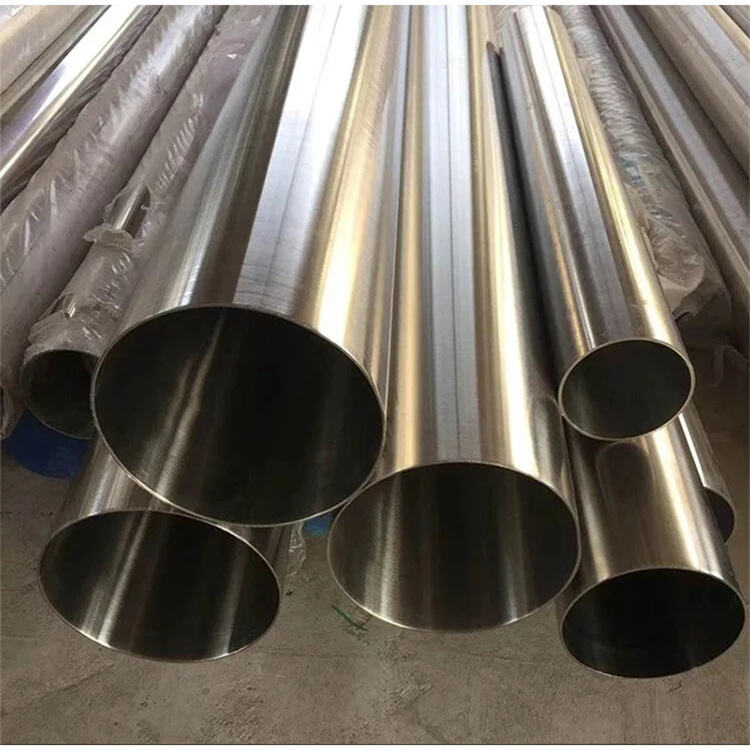

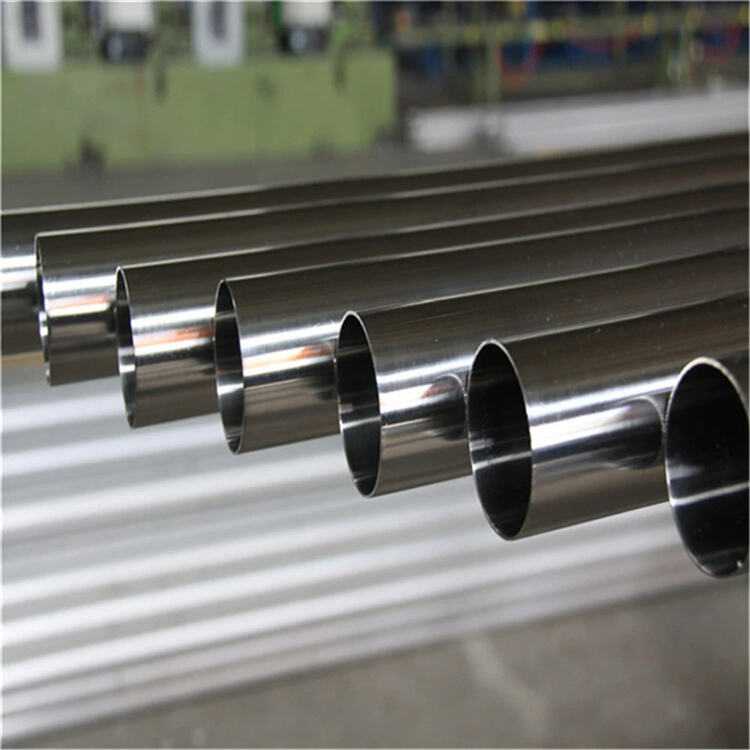

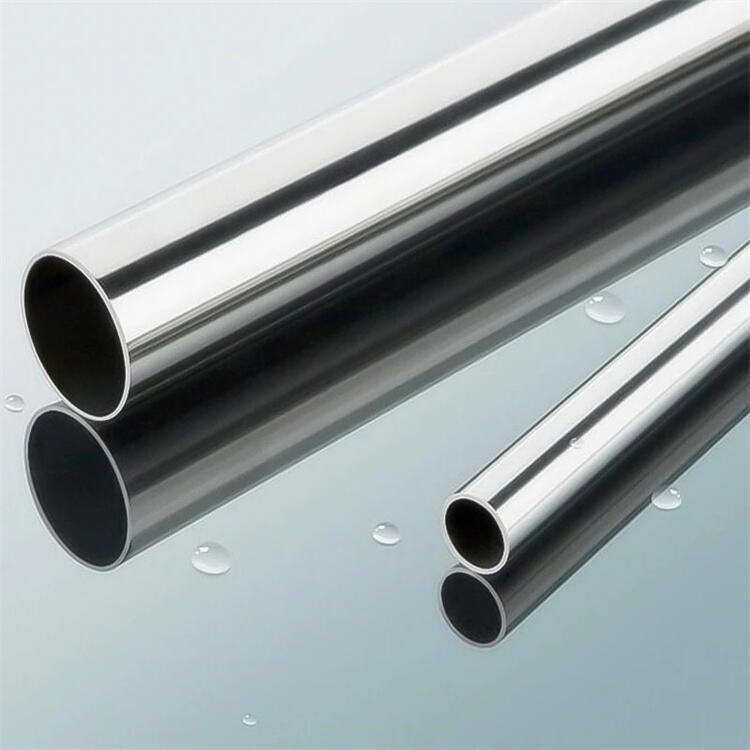

309 Stainless Steel Pipe

Grade 309 are austenitic chromium-nickel stainless steels, which are often used for high temperature applications. Due to their high chromium and nickel content, Grade 309 pipes are highly corrosion resistant, and have outstanding resistance to oxidation. In addition, they exhibit excellent heat resistance while providing good strength at ambient or elevated temperatures.

- Overview

- Related Products

Description:

Description:

Grade 309 are austenitic chromium-nickel stainless steels, which are often used for high temperature applications. Due to their high chromium and nickel content, Grade 309 pipes are highly corrosion resistant, and have outstanding resistance to oxidation. In addition, they exhibit excellent heat resistance while providing good strength at ambient or elevated temperatures.

Specifications:

Specifications:

|

Product Name |

309 Stainless Steel Pipe |

|

Dimensions |

ASTM, ASME and API |

|

SS 309 Tubes Size |

10.29 OD (mm) – 762 OD (mm) |

|

Thickness |

0.35 OD (mm) to 6.35 OD (mm) in thickness ranging from 0.1mm to 1.2mm. |

|

Schedule |

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Type |

Seamless / ERW / Welded / Fabricated |

|

Form |

Round Tubes, Custom Tubes, Square Tubes, Rectangular Tubes, “U” Shape, Hydraulic Tubes |

|

Length |

Single Random, Double Random & Cut Length. |

|

End |

Plain End, Beveled End, Treaded |

Equivalent Grades of SS309 Pipe:

|

STANDARD |

WERKSTOFF NR. |

UNS |

|

SS 309 |

1.4828 |

S30900 |

Chemical Composition of 309 Stainless Steel Tubes:

|

Grade |

C |

Ni |

Si |

S |

Mn |

P |

Cr |

Mo |

|

SS 309 |

0.20 max |

12.0 – 15.0 |

0.75 max |

0.03 max |

2.00 max |

0.045 max |

22.0 – 24.0 |

– |

Mechanical Properties of Stainless Steel 309 Tubes:

|

Grade |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

SS 309 |

8.0 g/cm3 |

1455°C (2650°F) |

Psi – 89900 , MPa – 620 |

Psi – 45000 , MPa – 310 |

45 % |

Applications:

Applications:

Stainless steel 309 is commonly used in heating elements, auto exhaust elements, boiler baffles, heat exchangers, refineries, and chemical processing in maritime industries, desalination plants, fertilizer facilities, and other industries.

SS 309 Tubes Value Added Services:

SS 309 Tubes Value Added Services:

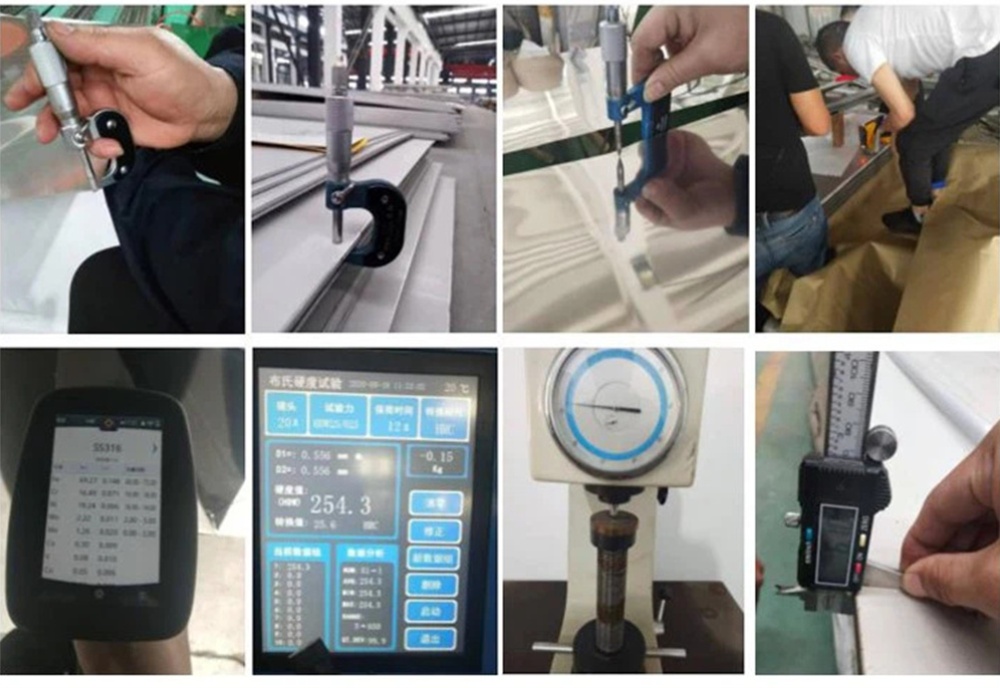

Material Testing:

Mechanical Testing Such as Tensile of Area

Mechanical Testing Such as Tensile of Area

Hardness Test

Hardness Test

Chemical Analysis – Spectro Analysis

Chemical Analysis – Spectro Analysis

Positive Material Identification – PMI Testing

Positive Material Identification – PMI Testing

Flattening Test

Flattening Test

Micro and MacroTest

Micro and MacroTest

Pitting Resistance Test

Pitting Resistance Test

Flaring Test

Flaring Test

Intergranular Corrosion (IGC) Test

Intergranular Corrosion (IGC) Test

Product Packing:

Product Packing:

FAQ:

FAQ:

1.Q: How long can make delivery?

A: For stock products, will make shipments in 5- 7 days after receiving deposit; for products need new production for common materials, usually make shipments in 10-15 days; for products need new production for special and rare materials, usually need 20-30 days to make shipment.

2.Q:Can I visit your factory?

A: Sure,welcome to you visit our factory at any time.

3.Q:Where are you?

A: Anyang in Henan Province.

4.Q: What certifications do your products have?

A: We have ISO 9001,BV, SGS, CE, TUV and other certifications.

5.Q:What are your terms of payment?

A:30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100%.Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A.

Tag:

309 Stainless Steel Pipe,China Stainless Steel Pipe manufacturers, suppliers, factory,Stainless Steel Tube,316 Stainless Steel Pipe, 304 Stainless Steel Pipe, 304L Stainless Steel Pipe,201 Stainless Steel Pipe,301 Stainless Steel Pipe,2205 Duplex Stainless Steel Pipe,310 Stainless Steel Pipe,310S Stainless Steel Pipe,Stainless Steel Seamless Pipe,Stainless Steel Welded Pipe,321 Stainless Steel Pipe,Stainless Steel Perforated Pipe/Tube,Stainless Steel Oval Tube/Pipe