C45 Carbon Steel Pipe

C45 is a high-strength medium-carbon high-quality steel specified in the European standard EN10083-2. It is suitable for manufacturing bearings, gears, pins and other parts. C45 steel can obtain good mechanical properties after heat treatment, and has high wear resistance and machinability.

- Overview

- Related Products

- Chemical analysis: to ensure that the composition meets the specified standards.

- Mechanical property testing: tensile, hardness and impact tests to verify mechanical properties.

- Non-destructive testing (NDT): ultrasonic and other non-destructive testing methods are used to detect internal defects.

- Dimensional inspection: to ensure that the pipe meets the specified size and tolerance requirements.

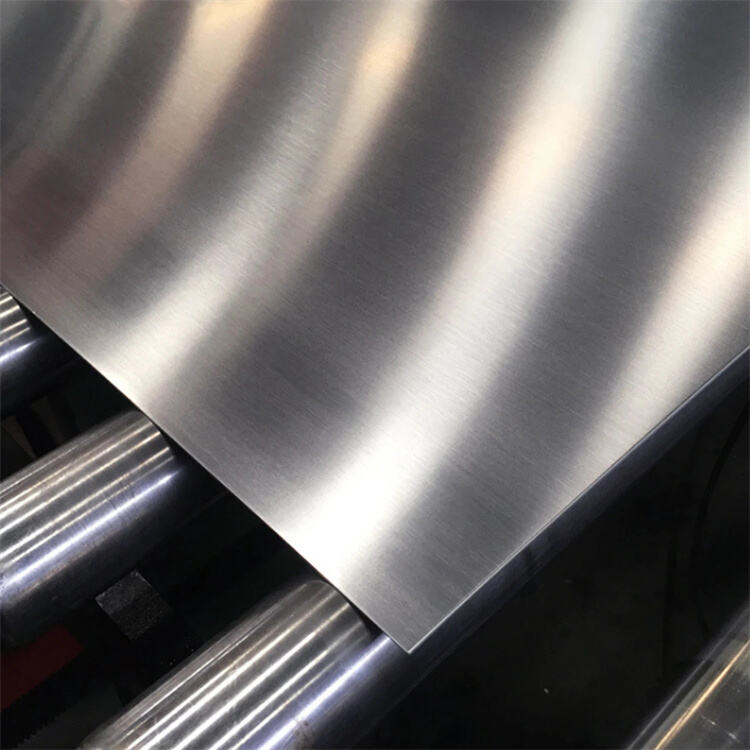

- Precision: cold-rolled precision steel pipes have high tolerance and dimensional accuracy, and the product accuracy is controlled at ±0.05 mm.

- Surface finish: both the inner and outer walls have good finish, and there is no oxide layer on the surface, ensuring a clean and smooth appearance.

- High pressure resistance: these pipes are able to withstand high pressure and are suitable for demanding applications.

- Deformation ability: they can withstand cold bending, expansion and flattening without cracking or wrinkling, allowing for a variety of complex deformation and machining.

- Material saving: Using precision seamless pipes helps save steel by efficiently utilizing materials.

- Processing efficiency: Improving processing efficiency and reducing processing steps can reduce equipment investment and save costs.

- Machining: Reducing machining time, increasing production volume and material utilization can help improve product quality and reduce overall costs.

Description:

Description:

C45 is a high-strength medium-carbon high-quality steel specified in the European standard EN10083-2. It is suitable for manufacturing bearings, gears, pins and other parts. C45 steel can obtain good mechanical properties after heat treatment, and has high wear resistance and machinability.

Specifications:

Specifications:

Product Name |

C45 Carbon Steel Pipe |

Standard |

EN, DIN, AISI, JIS, ASME GB, IS, ASTM Pipes |

Welded Pipes Size |

5.0 – 1219.2 mm |

Seamless Pipes Size |

4 to 219 mm W. T.: 0.5 to 20 mm |

EFW Pipes size |

5.0 – 1219.2 mm |

Schedule |

SCH80, SCH5, STD, SCH20, SCH10, SCH160, SCH120, SCH30, SCH40, SCH10S, SCH140, SCH40S, XXS XS, SCH80, SCH60, |

Seamless Tube Size |

3.35 OD To 101.6 mm OD |

Length |

Single , Double , Standard & Cut length Pipes & Tube |

Finish |

MF AP, Polished, BA |

Welded Tube Size |

6.35 mm OD To 152 mm OD |

wall thickness |

0.020 –0.220 inch |

C45 Chemical Composition:

Grade |

C |

Si |

Mn |

P |

S |

Mo |

Ni |

Cr |

C45 |

0.42-0.50 |

max 0.40 |

0.50-0.80 |

0.045 |

0.045 |

max 0.10 |

max 0.40 |

max 0.40 |

C45 Carbon Steel Tube Mechanical Properties:

Grade |

Tensile Strength |

Yield Strength |

Elongation |

Hardness |

C45 |

600-750 MPa |

340 MPa (minimum) |

16% (minimum) |

197 HB (Brinell hardness) |

C45 Carbon Steel Pipe Heat Treatment:

Grade |

Normalizing |

Quenching |

Tempering |

C45 |

840-880°C |

820-860°C |

550-660°C |

Applications:

Applications:

C45 is suitable for manufacturing bearings, gears, pins and other parts.

Quality Assurance:

Quality Assurance:

All C45 grade carbon steel pipes undergo rigorous testing and quality control measures to ensure that they meet the highest standards. These measures include:

Features of C45 Grade Carbon Steel Pipes:

Features of C45 Grade Carbon Steel Pipes:

1. High tolerance and dimensional accuracy

2. Excellent comprehensive performance

3. Efficient and cost-effective

Tag:

C45 Carbon Steel Pipe, China Carbon Steel PipeManufacturers, Suppliers, Factory, Carbon Steel, Carbon steel Tube,Carbon Steel Pipe,Q235 Carbon Steel Pipe,Q235A Carbon Steel Pipe,Q235B Carbon Steel Pipe,Q235C Carbon Steel Pipe,Q235D Carbon Steel Pipe,S335 Carbon Steel Pipe,A283 Carbon Steel Pipe