In modern industry, architecture, kitchenware and daily necessities, the word "Inox" appears more and more frequently in people's vision. It represents high-quality, corrosion-resistant and easy-to-clean metal materials. Many people wonder: What material is Inox? What is its relationship with stainless steel? In what scenarios is it most suitable? This article will explain Inox in detail, hoping to help everyone.

The word "Inox" originated from the French "Inoxydable", which means "not oxidized". It is another name for "stainless steel", especially in European countries. In global trade and industrial product descriptions, "Inox" has gradually become a general term used to represent various corrosion-resistant stainless steel materials. In international standards, stainless steel usually refers to iron alloy materials with a chromium content greater than 10.5% and a carbon content not exceeding 1.2%, and Inox is another name for this alloy.

The main elements of Inox include iron (Fe), chromium (Cr), nickel (Ni), etc. Chromium is the most important alloying element. When the chromium content reaches more than 10.5%, a dense chromium oxide film will form on the surface of the material. This passivation film can effectively resist external erosion such as oxidation and corrosion. The addition of nickel can further enhance the corrosion resistance and toughness of Inox, especially in low temperature environments. Depending on the type, molybdenum (Mo), titanium (Ti), manganese (Mn), nitrogen (N) and other elements may also be added to meet different usage requirements.

Inox can be mainly divided into the following categories according to its metallographic structure:

1. Austenitic Stainless Steel

Austenitic Inox is the most common type, with typical representatives such as 304 and 316. This type of steel has excellent corrosion resistance, good processability and welding performance, and is widely used in food equipment, medical equipment, architectural decoration and other fields.

2. Ferritic Stainless Steel

High chromium content, low nickel content or even no nickel, representative models such as 430, 446, etc. It has good corrosion resistance and oxidation resistance, and its price is lower than that of austenite. It is often used in kitchenware, automobile exhaust pipes and other fields.

3. Martensitic Stainless Steel

This type of Inox has high hardness and can be heat treated. It is often used in knives, shafts, medical equipment and other fields. Representative models are 410 and 420.

4. Duplex Stainless Steel

Combining the advantages of austenite and ferrite, it has high strength and good pitting resistance. Typical models are 2205, 2507, etc., and are often used in highly corrosive environments such as marine engineering and petrochemicals.

5. Precipitation Hardening Stainless Steel

The material has high strength and hardness through heat treatment, and is often used in aerospace, high-precision machinery and other fields.

Excellent Corrosion Resistance

Excellent Corrosion Resistance

Because Inox contains chromium and forms a passivation film, it can resist corrosion from a variety of chemical media, including acids, alkalis, salts, etc.

High Strength And Toughness

High Strength And Toughness

Inox can maintain good strength and ductility even at low or high temperatures, and is suitable for a variety of extreme environments.

Good Processing And Welding Performance

Good Processing And Welding Performance

Most Inox can be processed by cold processing, hot processing, stretching, bending and other processes, and are easy to weld, meeting the various needs of modern manufacturing.

Easy To Clean And Beautiful Appearance

Easy To Clean And Beautiful Appearance

Inox has a smooth surface, is easy to clean, and is not easy to breed bacteria. Therefore, it is widely used in places with high hygiene requirements such as kitchens and hospitals. Its metallic luster is also commonly used in the field of decoration.

Inox Vs. Carbon Steel:

Although Inox has a higher cost, its corrosion resistance is far better than carbon steel, which is prone to rust and requires regular maintenance. Inox has a lower cost over the entire life cycle.

Inox Vs. Aluminum Alloy:

Aluminum is light and has good thermal conductivity, but its strength and wear resistance are not as good as Inox, and aluminum alloy is not as resistant to high temperatures as Inox.

Inox Vs. Titanium Alloy:

Titanium alloy is strong and light, but the price is extremely high, and it is only used in specific high-end fields such as aerospace; while Inox is moderately priced and widely applicable, making it a more cost-effective choice.

Inox production process includes:

Melting: using electric arc furnace to melt raw materials such as iron ore, chromium ore, nickel ore, etc.;

Melting: using electric arc furnace to melt raw materials such as iron ore, chromium ore, nickel ore, etc.;

Refining: further removing impurities through AOD or VOD and other technologies;

Refining: further removing impurities through AOD or VOD and other technologies;

Casting: forming preliminary ingots or slabs;

Casting: forming preliminary ingots or slabs;

Hot rolling and cold rolling: hot rolling or cold rolling according to product requirements;

Hot rolling and cold rolling: hot rolling or cold rolling according to product requirements;

Solution treatment: eliminate internal stress and improve material properties;

Solution treatment: eliminate internal stress and improve material properties;

Surface treatment: pickling, polishing, wire drawing, sandblasting and other treatments to meet different appearances and uses.

Surface treatment: pickling, polishing, wire drawing, sandblasting and other treatments to meet different appearances and uses.

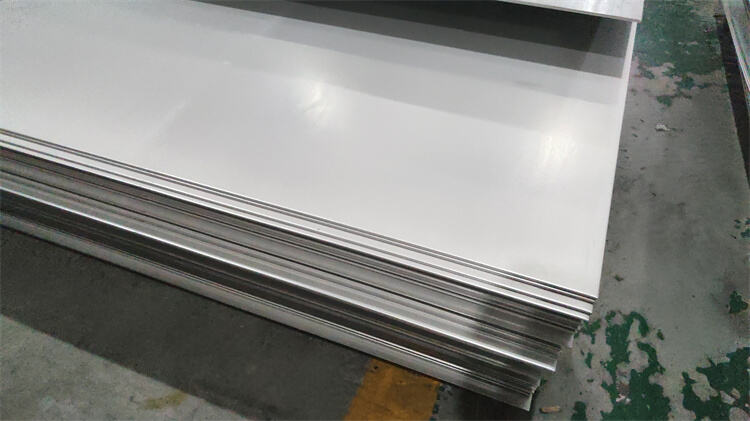

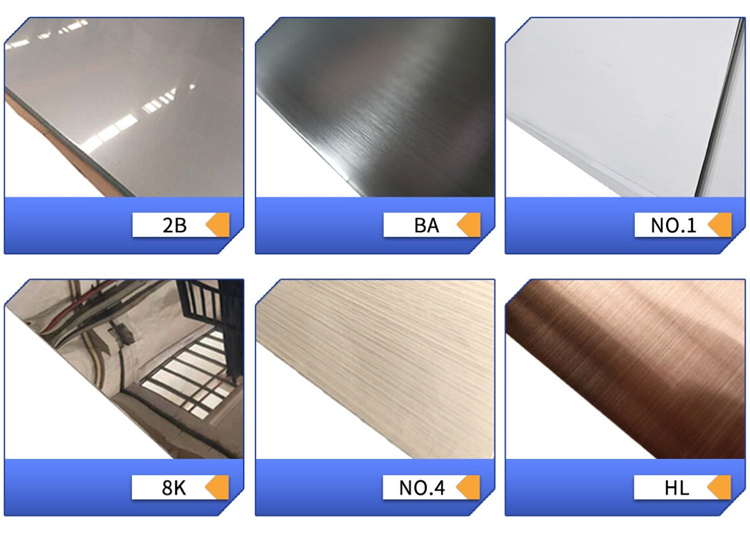

2B: a smoother surface obtained by cold rolling, heat treatment and pickling, and then finishing rolling.

BA (Bright Annealed): Bright annealed surface, suitable for high reflective requirements.

No.4: Frosted surface, decorative, commonly used in elevators, cabinets, etc.

HL (Hair Line): Hairline treatment, commonly used for building exterior wall decoration.

8K mirror: High-gloss mirror treatment, often used for high-end decoration and art products.

Architecture and decoration

Architecture and decoration

High-rise building facades, curtain walls, elevator doors, handrails, ceilings, railings, etc. all use Inox materials in large quantities, which are not only beautiful but also durable.

Kitchenware and tableware

Kitchenware and tableware

Inox is corrosion-resistant, rust-free, and easy to clean. It can be used to make pots, knives, plates, and spoons.

Medical industry

Medical industry

Inox is not easy to breed bacteria and is widely used in surgical instruments, beds, infusion stands, etc.

Chemical and petroleum industry

Chemical and petroleum industry

Inox can resist acid and alkali corrosion and is used in chemical reaction vessels, pipelines, storage tanks and other equipment.

Automobile and railway

Automobile and railway

It is used in exhaust systems, interior parts, body reinforcements, etc. to improve automobile safety and durability.

Aerospace

Aerospace

Some high-performance Inox alloys can be used to manufacture aircraft parts, fuel tanks, brackets, etc.

Although Inox has good corrosion resistance, it does not mean "never rust". In high salt, acid, alkali, hot and humid environments, if stains, grease or metal particles accumulate on the surface, "floating rust" may also occur. Therefore, the following points should be noted in daily life:

Inox is not only a synonym for a stainless steel material, but also represents a material philosophy of high quality, long life, safety and environmental protection. From kitchens to chemical plants, from homes to the aviation industry, Inox always plays an irreplaceable role.

HNJBL is a professional steel manufacturer and supplier. Our company's main products include carbon steel, stainless steel, wear-resistant steel, steel profiles, coated steel, etc. Complete specifications, stable quality, and sufficient quantity.

Hot News

Hot News2025-06-10

2025-06-04

2025-05-26

2025-05-19

2025-05-14

2025-05-06

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy