Duplex stainless steel is a type of stainless steel whose microstructure consists of two phases, ferrite and austenite, usually accounting for about 50% each. This duplex structure gives duplex stainless steel unique properties while maintaining the properties of both ferrite and austenite stainless steels.

The composition design of duplex stainless steel usually includes higher chromium, molybdenum and nitrogen content to improve its corrosion resistance while maintaining good mechanical properties. This material is often used to manufacture equipment and components that require high strength and high corrosion resistance.

The characteristics of duplex stainless steel are mainly manifested in the following aspects:

High strength: Duplex stainless steel has higher yield strength and tensile strength than ordinary austenitic stainless steel. Its yield strength is usually twice that of austenitic stainless steel, which means that under the same stress conditions, duplex stainless steel can use thinner materials, thereby saving costs.

High strength: Duplex stainless steel has higher yield strength and tensile strength than ordinary austenitic stainless steel. Its yield strength is usually twice that of austenitic stainless steel, which means that under the same stress conditions, duplex stainless steel can use thinner materials, thereby saving costs.

Excellent corrosion resistance: Duplex stainless steel exhibits excellent resistance to stress corrosion cracking in many corrosive environments, especially in chloride ion and sulfuric acid environments. This is due to its unique duplex structure that can effectively inhibit the propagation of cracks.

Excellent corrosion resistance: Duplex stainless steel exhibits excellent resistance to stress corrosion cracking in many corrosive environments, especially in chloride ion and sulfuric acid environments. This is due to its unique duplex structure that can effectively inhibit the propagation of cracks.

Good toughness: Despite its high strength, duplex stainless steel maintains good toughness and ductility. This is because its austenite phase provides superior toughness, while the ferrite phase provides high strength.

Good toughness: Despite its high strength, duplex stainless steel maintains good toughness and ductility. This is because its austenite phase provides superior toughness, while the ferrite phase provides high strength.

Good welding performance: Duplex stainless steel has good welding performance and is suitable for a variety of welding methods, including manual arc welding, gas shielded welding and laser welding. During welding, it is necessary to pay attention to controlling the heat input to avoid an imbalance in the proportion of austenite and ferrite phases in the heat affected zone of welding.

Good welding performance: Duplex stainless steel has good welding performance and is suitable for a variety of welding methods, including manual arc welding, gas shielded welding and laser welding. During welding, it is necessary to pay attention to controlling the heat input to avoid an imbalance in the proportion of austenite and ferrite phases in the heat affected zone of welding.

There are many grades of duplex stainless steel. Common duplex stainless steel grades include: 2205, 2507, 3RE60, etc. The following is a table of their chemical composition and mechanical properties.

Chemical composition:

|

Grade |

C≤ |

Mn≤ |

Si≤ |

S≤ |

P≤ |

Cr≤ |

Ni |

Mo |

Cu≤ |

N |

|

S32750(SAF2507) 00Cr25Ni7Mo4N |

0.03 |

1.20 |

0.8 |

0.020 |

0.035 |

24.0/26.0 |

6.0/8.0 |

3.0/5.0 |

0.50 |

0.24/0.32 |

|

S31803(SAF2205) 00Cr22Ni5Mo3N |

0.03 |

2.00 |

1.0 |

0.020 |

0.030 |

21.0/23.0 |

4.50/6.50 |

2.50/3.50 |

|

0.08/0.20 |

|

S31500(3RE60) 00Cr18Ni5Mo3Si2 |

0.03 |

1.2/2.00 |

1.4/2.00 |

0.030 |

0.030 |

18.0/19.0 |

4.25/5.25 |

2.50/3.00 |

|

0.05/0.10 |

Mechanical properties:

|

Grade |

σb(Mpa)≥ |

σs(Mpa)≥ |

δ(%)≥ |

Hardness |

|

|

Brinell(HB) |

Rockwell(HRC) |

||||

|

S32750(SAF2507) 00Cr25Ni7Mo4N |

800 |

550 |

15 |

310 |

32 |

|

S31803(SAF2205) 00Cr22Ni5Mo3N |

620 |

450 |

25 |

290 |

30.5 |

|

S31500(3RE60) 00Cr18Ni5Mo3Si2 |

630 |

440 |

30 |

290 |

30.5 |

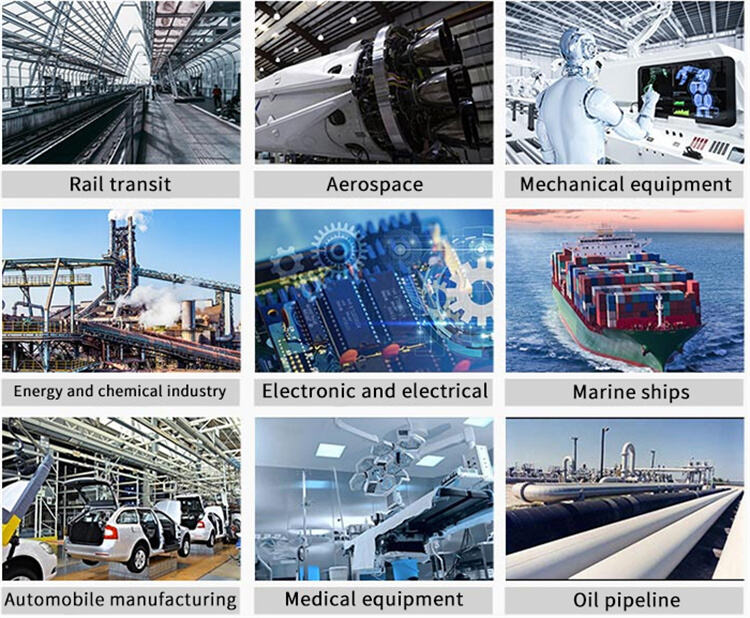

Duplex stainless steel is widely used in many fields:

Oil and gas industry: used to manufacture oil pipelines, storage tanks, submarine pipelines, etc.

Oil and gas industry: used to manufacture oil pipelines, storage tanks, submarine pipelines, etc.

Chemical industry: used to manufacture chemical equipment, storage tanks, reactors, etc.

Chemical industry: used to manufacture chemical equipment, storage tanks, reactors, etc.

Shipbuilding industry: used to manufacture ship structures, storage tanks, etc.

Shipbuilding industry: used to manufacture ship structures, storage tanks, etc.

Construction industry: used to manufacture building structures, bridges, etc.

Construction industry: used to manufacture building structures, bridges, etc.

Food and beverage industry: used to manufacture food processing equipment, storage tanks, etc.

Food and beverage industry: used to manufacture food processing equipment, storage tanks, etc.

Processing:

Duplex stainless steel has good processing performance, but the following points should be noted:

Cutting: Due to the high strength and hardness of duplex stainless steel, it is necessary to select appropriate tool materials and cutting parameters during cutting.

Cutting: Due to the high strength and hardness of duplex stainless steel, it is necessary to select appropriate tool materials and cutting parameters during cutting.

Forming: Duplex stainless steel has good forming performance, but its high strength and hardness need to be considered during cold forming, and higher forming force and suitable lubrication conditions may be required.

Forming: Duplex stainless steel has good forming performance, but its high strength and hardness need to be considered during cold forming, and higher forming force and suitable lubrication conditions may be required.

Heat treatment:

The heat treatment process of duplex stainless steel has an important influence on its performance. Common heat treatment methods include solution treatment and aging treatment.

Solution treatment: By heating to 1100-1200℃ and then cooling rapidly (cooling is usually done by water or air to prevent harmful phases from being washed out), the alloy elements in the steel are completely dissolved in the austenite and ferrite matrix, eliminating internal stress and improving the corrosion resistance and toughness of the steel.

Solution treatment: By heating to 1100-1200℃ and then cooling rapidly (cooling is usually done by water or air to prevent harmful phases from being washed out), the alloy elements in the steel are completely dissolved in the austenite and ferrite matrix, eliminating internal stress and improving the corrosion resistance and toughness of the steel.

Aging treatment: Heating and keeping warm at a temperature lower than the solution treatment temperature promotes phase transformation and precipitation hardening, and improves the strength and hardness of the steel. The temperature is generally between 600-900℃.

Aging treatment: Heating and keeping warm at a temperature lower than the solution treatment temperature promotes phase transformation and precipitation hardening, and improves the strength and hardness of the steel. The temperature is generally between 600-900℃.

Duplex stainless steel has obvious advantages over austenitic stainless steel and ferritic stainless steel.

Austenitic stainless steel has good toughness and corrosion resistance, but lower strength;

Austenitic stainless steel has good toughness and corrosion resistance, but lower strength;

Ferritic stainless steel has higher strength, but its toughness and corrosion resistance are not as good as austenitic stainless steel.

Ferritic stainless steel has higher strength, but its toughness and corrosion resistance are not as good as austenitic stainless steel.

Duplex stainless steel has the advantages of both through its duplex structure.

Duplex stainless steel has the advantages of both through its duplex structure.

By understanding the various aspects of duplex stainless steel, it can be seen that it plays an increasingly important role in modern industry. Duplex stainless steel not only has high strength, excellent corrosion resistance and good toughness, but also can adapt to various harsh use environments.

If you want to know more about stainless steel plate/pipe, please contact us!

Hot News

Hot News2025-06-10

2025-06-04

2025-05-26

2025-05-19

2025-05-14

2025-05-06

Copyright © Henan Jinbailai Industrial Co.,Ltd. All Rights Reserved - Privacy Policy